Peter Egner, Head of Supply Chain Management and Logistics Automotive at the Schaeffler Group, wanted to know: How can transport between the plants in Bühl and Szombathely in Hungary be organised in a more climate-friendly way? Together with project partners Logistik Schmitt and Kombiverkehr, he pitted the lorry and rail modes of transport against each other to evaluate them in terms of transit time, price and emissions savings. The first test transport started on 18 February 2022 in Bühl and was covered by the trade journal trans aktuell (read more).

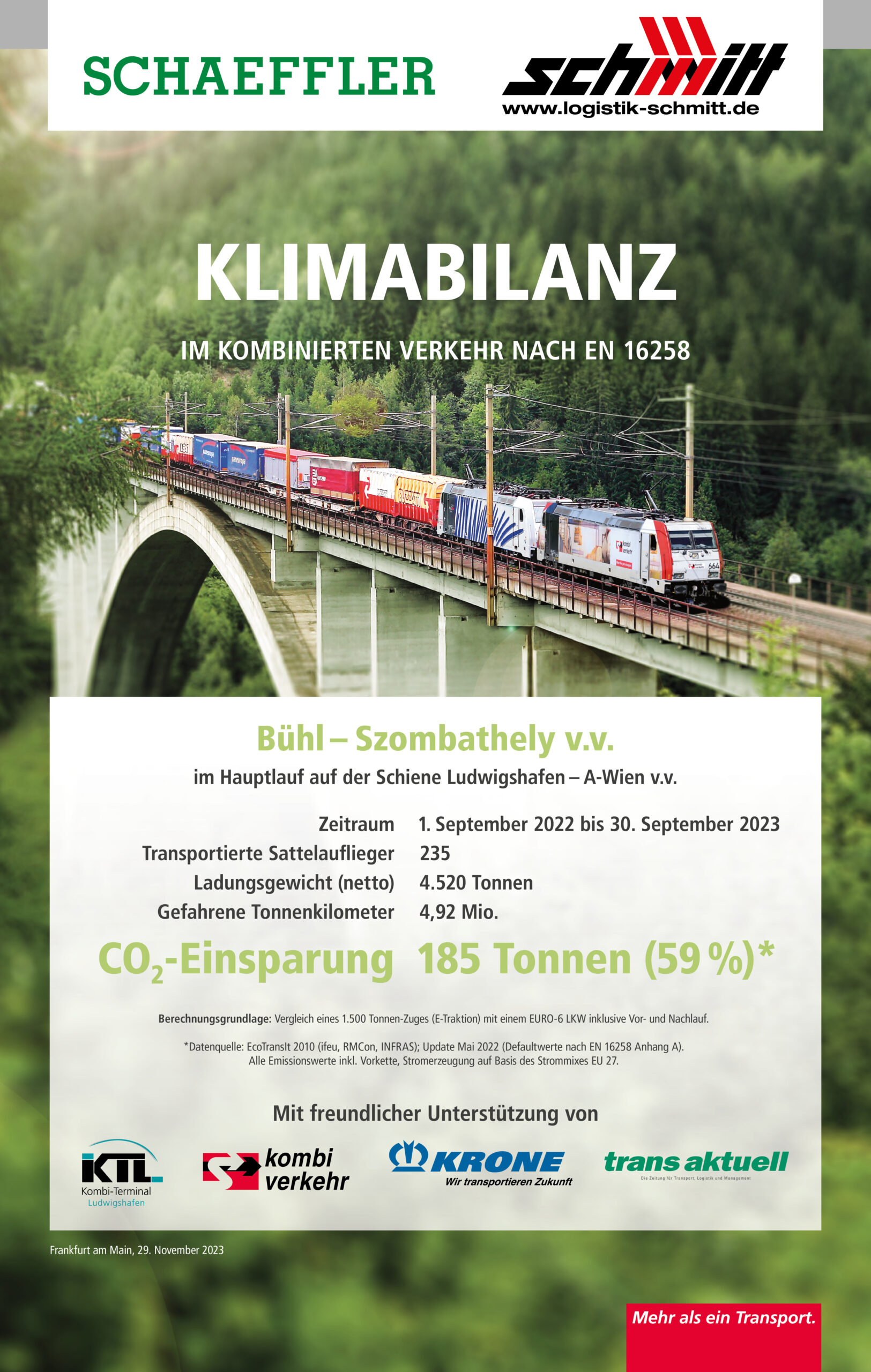

Once the conditions for a longer pilot operation had been created, Logistik Schmitt tractor units transported trailers three times a week from Bühl to the Ludwigshafen intermodal terminal by road in the project period from the beginning of September 2022 to the end of September 2023. From there, the main leg of the journey continued by rail over 800 kilometres via Wels to Vienna. From Vienna, the semi-trailers loaded with stamped metal parts reached the plant in Szombathely via a contracted trucking company. After unloading and reloading, empty containers for the Bühl site were transported back to Germany on the same route.

Meeting at Schaeffler, Bühl

Peter Egner, Schaeffler, and Matthias Rathmann, trans aktuell

Volker Klemm, Logistik Schmitt

Rainer Schmitt, Logistik Schmitt

Benjamin Sommer, Logistik Schmitt

Jan Weiser, Kombiverkehr

Ulrich Bedacht, Kombiverkehr

Harald Schlegel, Kombiterminal Ludwigshafen

In November, all project partners met again in Bühl to share the knowledge gained from the project and to discuss the next steps. The many statements made showed that the goal of reducing emissions has been realised and that Schaeffler has made the transport chain a good deal greener. Peter Egner is aware that sustainable logistics solutions also have their price. The company is endeavouring to further intensify intermodal transport, especially as the transit times of rail transport are quite comparable to continuous road transport, depending on the day of dispatch.

“It’s impressive to see how quickly and successfully a project can be realised when everyone involved is passionate about the topic.”

Matthias Zink, CEO Automotive Technologies at the Schaeffler Group

“The ‘Train by Train’ project has enabled us to make significant CO2 savings.”

Peter Egner, Head of Supply Chain Management and Logistics Automotive at the Schaeffler Group

Within one year – from 1 September 2022 to 30 September 2023 – Schaeffler’s Automotive division has reduced its carbon footprint by 185 tonnes. 185 tonnes of CO2 – that’s roughly the amount produced by around 6,000 people in Germany every day. This is also roughly the size of Schaeffler’s workforce at the Bühl site. A total of 235 semi-trailers used the railway instead of the road during the project period. A total of 4,520 tonnes were moved.

“By using combined transport, we were able to achieve a 59 per cent reduction in CO2 emissions.”

BENJAMIN SOMMER, PROJECT MANAGER AT SCHMITT LOGISTICS

“This is a great success for everyone involved.”

Jan Weiser, Head of Corporate Communications Kombiverkehr KG

Regular operation with new electric lorry

Schaeffler has the potential for five lorries a day on the connection between Bühl and Szomathely, reported logistics manager Peter Egner, who immediately announced regular operations during the meeting. This is to be increased to two trailers per train departure in the coming year. Logistik Schmitt announced that the pre-carriage and onward carriage on the German side would be carried out using electric lorries in future. This would optimise the transport chain by a further CO2 factor, as Logistik Schmitt is investing in green electricity at its site in Bieitigheim. With a range of around 350 kilometres, the pre-carriage and onward carriage can be carried out completely electrically.

“The plan is that from now on, we will only use electric lorries for the pre-carriage and onward carriage to and from Ludwigshafen.”

Rainer Schmitt, Managing Director Logistics Schmitt

If you are interested in shifting transport from road to climate-friendly rail, simply get in touch with us. Your contact is Christian Lipinski, Head of Sales Management, +49 69/79505-245 or clipinski@kombiverkehr.de

Comments are closed.